Description

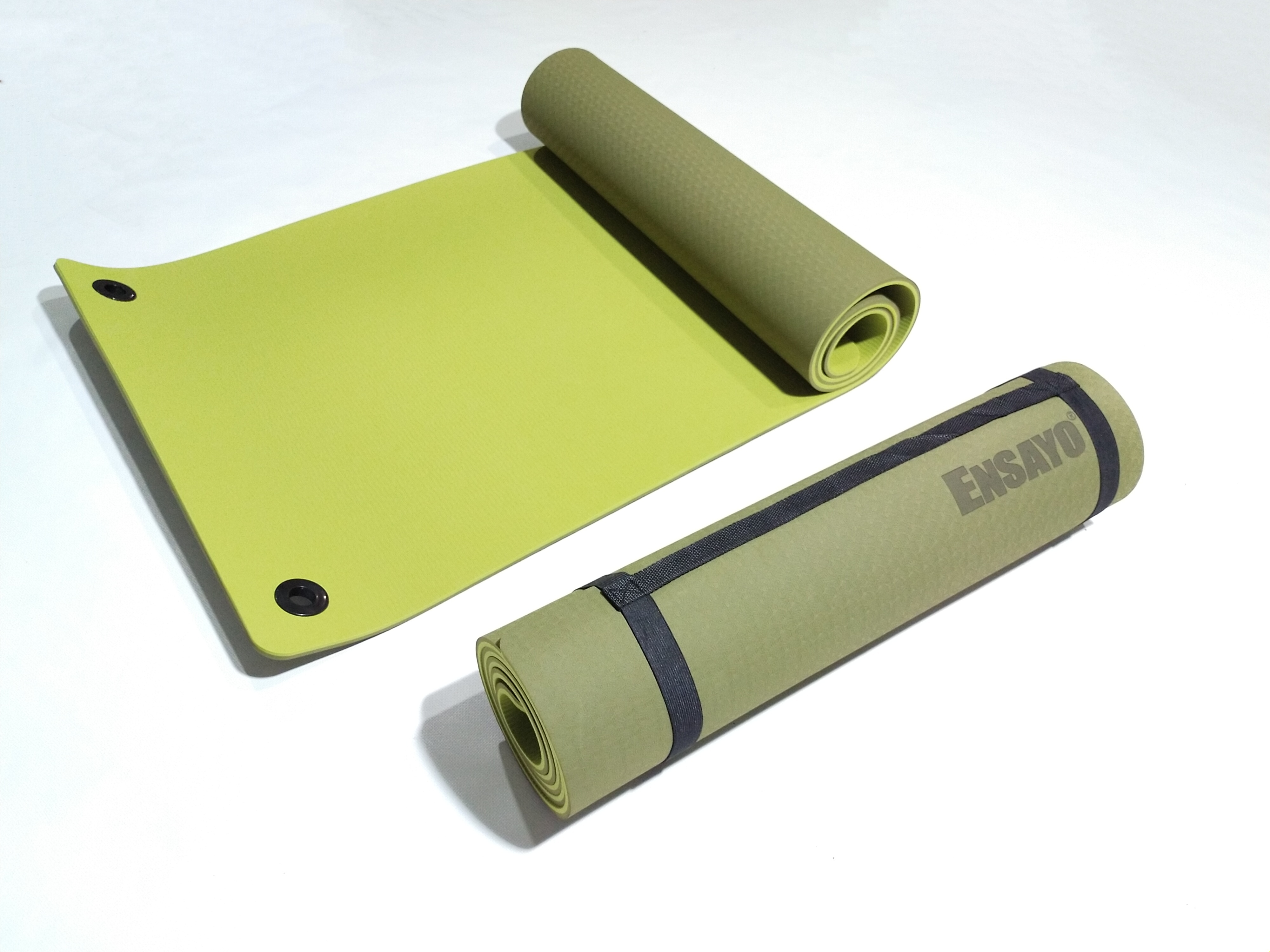

Thickness: 8mm

Length: 173cm

Width: 61cm

Weight: 1.2 kg.

Comes with 2 Ring Holes for easy to hang dry use.

Color Choices:

Dark Purple & Pink Combi

Sexy Red & Black Combi

Olive Green & Macha Combi

Light Brown & Peach Combi

Charcoal Black & Grey Combi

The Best Raw Material for Yoga Mats is Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection molding.

Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials.

The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties.

A more affordable yet comfortable type of raw material for yoga mats are Nitrile butadiene rubber (NBR) It is a family of unsaturated copolymers of 2-propenenitrile and various butadiene monomers (1,2-butadiene and 1,3-butadiene). Although its physical and chemical properties vary depending on the polymer’s composition of nitrile, this form of synthetic rubber is unusual in being generally resistant to oil, fuel, and other chemicals (the more nitrile within the polymer, the higher the resistance to oils but the lower the flexibility of the material).

It is used in the automotive and aeronautical industry to make fuel and oil handling hoses, seals, grommets, and self-sealing fuel tanks, since ordinary rubbers cannot be used.[1] It is used in the nuclear industry to make protective gloves. NBR’s ability to withstand a range of temperatures from −40 to 108 °C (−40 to 226 °F) makes it an ideal material for aeronautical applications. Nitrile butadiene is also used to create moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats.

Its resilience makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids, and has superior strength, but has inferior flexibility. Nitrile gloves are therefore more puncture-resistant than natural rubber gloves, especially if the latter are degraded by exposure to chemicals or ozone.[citation needed] Nitrile rubber is less likely to cause an allergic reaction than natural rubber.

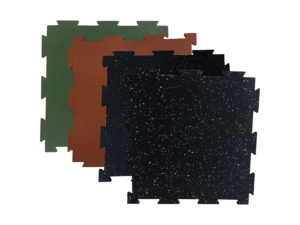

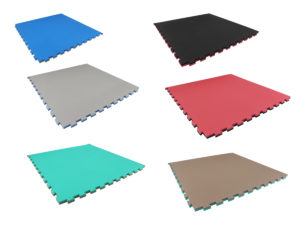

8mm Thick x 183cm Length x 61cm Width in Single colors. Weigh only 600 grams.

Deep Sea Turquoise

Dark Blue

Pretty Pink